The choice of reflective layer material in a blank CD or DVD is a critical factor influencing the disc's reliability. The reflective layer directs the laser beam back to the photosensor in the laser head. If this reflection is not precise and consistent, the disc may experience errors when writing or reading data.

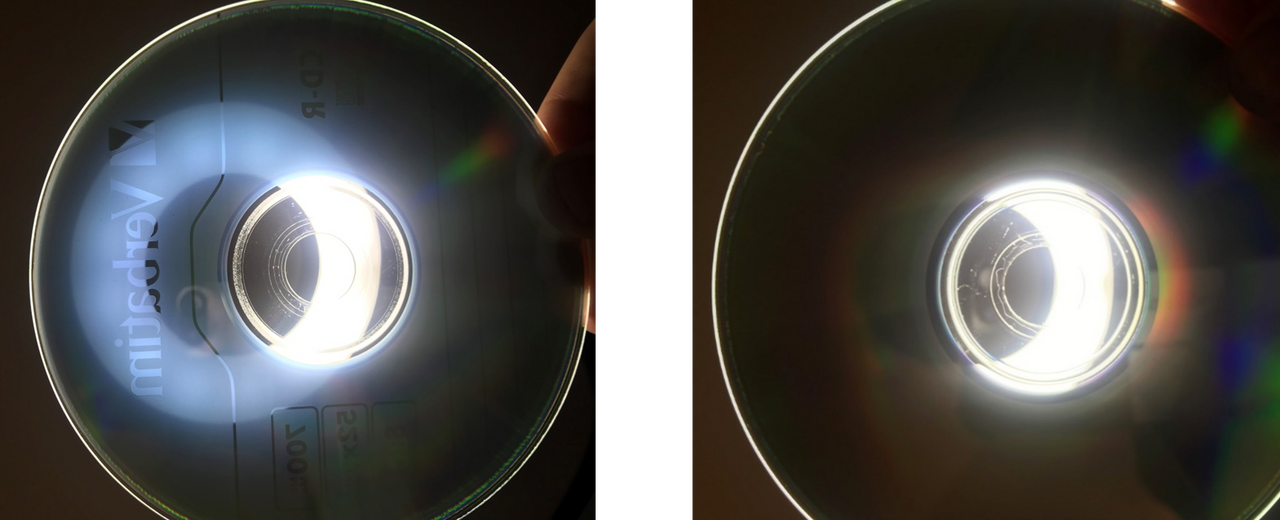

Reflective layers are typically made from either aluminium or silver. Aluminium layers are generally less expensive, whereas silver layers offer superior reflectivity, improving both reading and writing performance. The key question is whether these performance benefits justify the higher price of silver-based media.

It's also important to consider that lasers in optical drives degrade over time, becoming less powerful. Therefore, understanding how well optical discs perform in both newer and older drives is crucial for evaluating long-term reliability.